Select Language:

Calcium carbonate (limestone) is the most widely used mineral in the paper, plastics, paints and coatings industries both as a filler – and due to its special white color – as a coating pigment. In the paper industry it is valued worldwide for its high brightness and light scattering characteristics, and is used as a filler to make bright opaque paper. Filler is used at the wet-end of paper making machines, and calcium carbonate filler allows for the paper to be bright and smooth. As an extender, calcium carbonate can represent as much as 30% by weight in paints. Calcium carbonate also is used widely as a filler in adhesives, and sealants.

Calcium carbonate is critical to the construction industry, both as a building material (e.g. marble), and as a raw material of cement. It contributes to the making of mortar used in bonding bricks, concrete blocks, stones, roofing shingles, rubber compounds, and tiles. Calcium carbonate decomposes to form carbon dioxide and lime, an important material in making steel, glass, and paper. Because of its antacid properties, calcium carbonate is used in industrial settings to neutralize acidic conditions in both soil and water.

STET Dry Calcium Carbonate Beneficiation / Limestone:

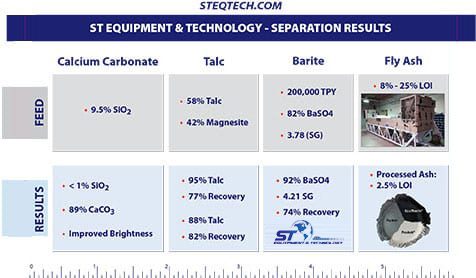

The STET separator has been successfully for the removal of quartz and other acid-insoluble contaminants from finely ground calcium carbonate used as a filler or whitening agent. Acid insoluble (AI) testing is a standard method of measuring the amount of undesirable contaminants in calcium carbonate. Silicates, such as quartz, mica, and talc, tribo-charge strongly negative relative to carbonates and successful separations have been achieved on sources of calcium carbonate tested at the pilot-scale and in a demonstration plant. Improvement in product brightness is also achieved for many sources of calcium carbonate beneficiation as the tribo-electrostatic belt separation technology is also effective in removing trace amounts of dark contaminates such as graphite and metal sulfides. Monthly average results for a pilot-scale continuously operating separator processing calcium carbonate is shown below in the table. This demonstration plant used a continuously operating STET pilot-scale separator with average feed rate 10 tons per hour.

The STET separator has also been proven in removing silicates and other contaminants from cement rock limestone prior to calcination, to extend the life and maximize recovery from cement rock deposits.

Contact us today to learn more about how STET can help with your limestone / calcium carbonate processing operation.

| Month | Avg. Feed grade (%AI) | Avg. Product grade (%AI) | Product Mass Yield (wt.%) | Calcium Carbonate Recovery (%) | AI Rejection to By- Product (%) |

|---|---|---|---|---|---|

| Month 1 | 3.3% | 0.6% | 86% | 89% | 84% |

| Month 2 | 3.7% | 0.6% | 89% | 92% | 87% |

| Month 3 | 4.1% | 0.6% | 89% | 92% | 88% |

| Month 4 | 4.0% | 0.7% | 89% | 92% | 84% |

| Month 5 | 4.7% | 0.6% | 89% | 93% | 89% |